Centrifugal Pump Selection: What Is an Efficiency Island?

Preface

Centrifugal pumps rarely operate at peak load. In fact, pumps typically only run at peak load about 5% of the time. Therefore, selecting a pump based solely on its performance at peak load is irrational. A wiser approach is to consider a broader range of operating conditions, including peak load.

This method of pump selection based on multiple operating conditions usually brings more significant energy savings than focusing only on the single Best Efficiency Point (BEP). Instead of only paying attention to the intersection of the system curve and the BEP, we should focus on a wider operating range, which constitutes the so-called "efficiency island."

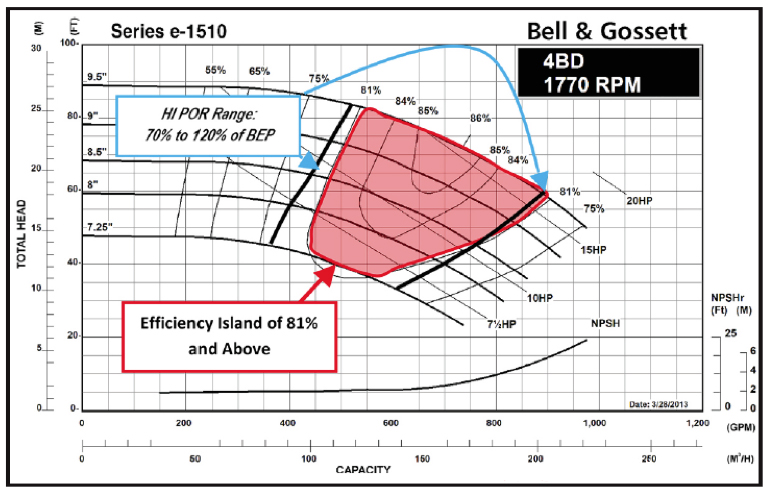

The efficiency island is vertically constrained by the performance of the minimum and maximum impeller diameters, and horizontally limited by isoefficiency lines—these concentric elliptical curves "surround" the BEP. Isoefficiency lines are based on the preferred operating range of the pump as defined by the Hydraulic Institute, which is specified as 70% to 120% of the pump's BEP flow rate.

In Figure 1, the red shaded area represents the efficiency island of a given pump.

Figure 1: Efficiency Island (red shaded area) of a Given Pump

Interaction Between the Efficiency Island and System Curves

The efficiency island can be combined with system curves to select a pump that operates efficiently across most of the system's load range.

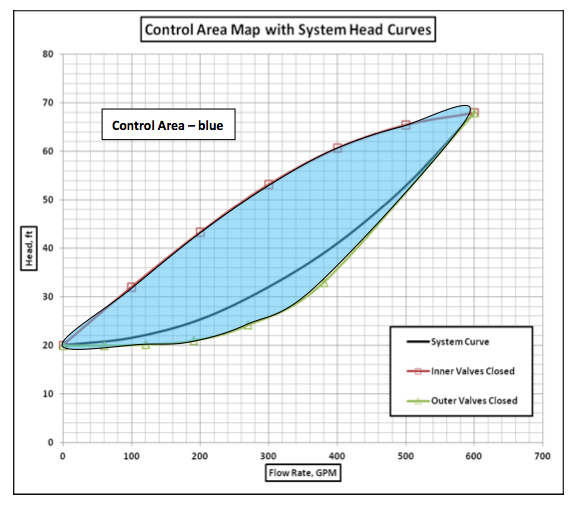

We know that a pump always operates at the intersection of its curve and the system curve. However, in most systems, the system curve is dynamic because valves open or close in response to changing demands. Therefore, when selecting a pump, we must consider the entire operating range of the system, which is defined by the control curve (see Figure 2).

Figure 2: Range of System Curves

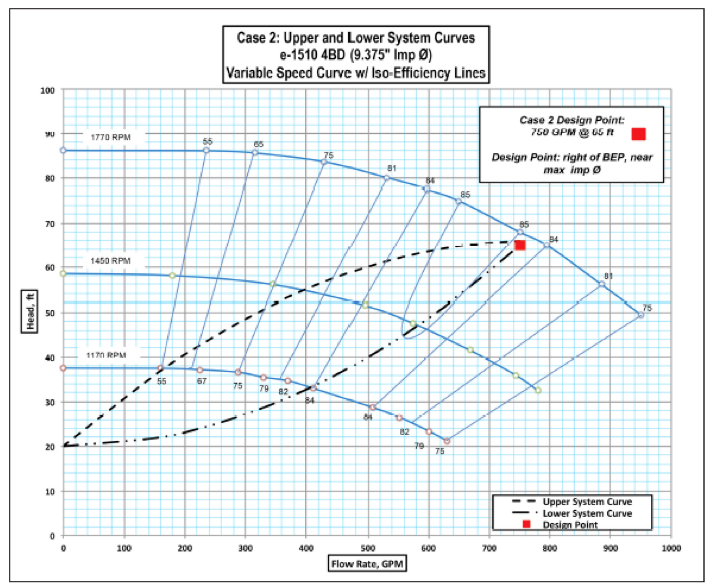

If we transpose the upper and lower system curves on a given pump curve, as shown in Figure 3, it becomes clear that the pump with the deepest and widest efficiency island will achieve the best overall operating efficiency. This essentially expands the cross-sectional area between the control curve and the efficiency island. If high efficiency is limited to a narrow flow range, the pump's efficiency will drop rapidly as the impeller diameter decreases. This is particularly important when selecting pumps with Variable Frequency Drives (VFDs), as VFDs allow pumps to operate as if they had different impeller trims.

Figure 3: Pump Selection by Combining Efficiency Island and System Curves

Note that the design point in Figure 3 is outside the pump's BEP. This is entirely acceptable because the pump will return to a more efficient "efficiency island" when unloaded—even at 50% of the 750 GPM design flow, it can still maintain 82% efficiency.