Centrifugal Pump Technology: Factors Affecting Radial Force in Centrifugal Pumps

From industrial processes to commercial water supply systems, centrifugal pumps, as the main machinery driving fluid movement, have a wide range of applications. At the core of these machines lies an often overlooked yet crucial aspect for their optimal operation: radial thrust. This force arises from unbalanced internal forces within pump components and significantly impacts the pump’s performance and service life. Understanding the complex dynamics of radial thrust is essential for engineers, maintenance personnel, and anyone involved in the design, operation, or maintenance of pump systems.

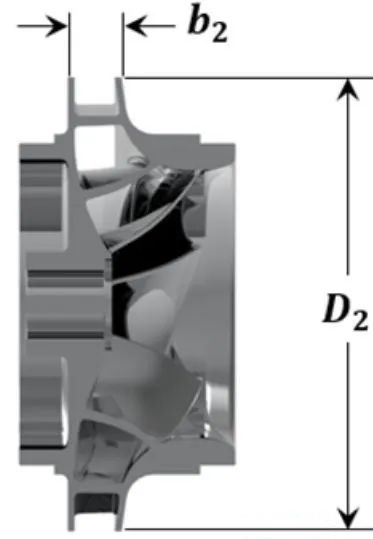

Radial thrust, characterized as being perpendicular to the rotating shaft within the pump casing or diffuser (guide vane), is influenced by a combination of factors (see Figure 1). The impeller’s design, outer diameter (D2), width (b2), structure, and the type of pump casing all affect the behavior of radial thrust (see Figure 2). The magnitude and direction of radial thrust fluctuate across the pump’s operating range, making it a key consideration in the engineering design and maintenance of these systems.

Figure 1: Hydraulic Radial Force in a Double Volute

Figure 2: Radial Impeller Outer Diameter (D2) and Impeller Outlet Width (b2)

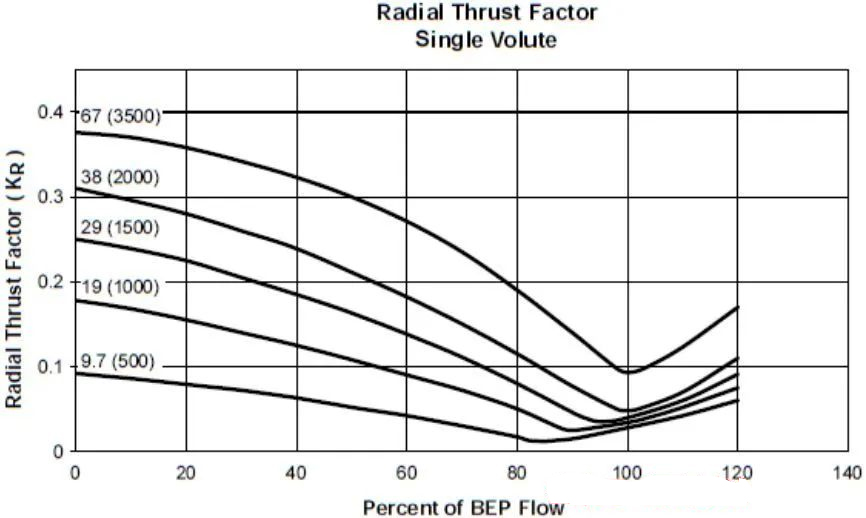

One of the key factors determining radial thrust is flow rate. At the Best Efficiency Point (BEP)—the flow rate at which the pump operates with peak efficiency—radial thrust is typically minimized. Figure 3 shows the radial thrust coefficients for a single volute, indicating that radial thrust increases as flow rate deviates from the BEP, exerting varying pressures on the impeller and surrounding components. Operating at flow rates significantly below the BEP amplifies these forces, leading to increased shaft stress, potential bearing and mechanical seal issues, and heightened vibration.

Figure 3: Radial Thrust Coefficients for Single Volutes at Different Specific Speeds

Operating pumps under extreme conditions, such as at shut-off or beyond the Allowable Operating Region (AOR), poses additional challenges. Running outside the AOR—especially at low-flow conditions—not only increases radial thrust but also causes overheating of the fluid inside the pump. Mitigation strategies, such as adding recirculation lines (bypasses) or using variable-speed controllers, help alleviate these effects, thereby extending the pump’s service life.

The pump’s intricate design plays a vital role in managing radial thrust. For example, the pump casing configuration—whether single volute, double volute, or concentric casing—significantly affects pressure distribution, which in turn influences radial forces on the impeller (see Figure 4). Single volutes typically exhibit maximum radial thrust at zero flow, while double volutes or concentric casings tend to reduce such loads across the entire operating range. Additionally, different casing designs, such as annular casings or modified concentric casings, exert unique effects on radial thrust.

Figure 4: Pump Casings (Single Volute, Double Volute)

Furthermore, the relationship between impeller diameter, rotational speed, and the resulting thrust is more complex. Changes in impeller outer diameter or pump speed directly affect radial thrust, albeit with different proportions: changes in impeller diameter impact thrust by a cubic relationship, while changes in speed affect thrust by a square relationship.

The complexity of vertical pumps, particularly suspended vertical turbine pumps, presents unique considerations. The multi-vane bowl diffusers of vertical pumps balance pressure, thereby significantly reducing radial thrust. However, over time, factors such as erosion, corrosion, or mechanical imbalance can induce radial thrust in the rotor.

The installation of vertical pumps introduces varying degrees of influence on radial thrust. An ideal vertical suspension minimizes radial forces on the rotor, but any deviation from vertical alignment due to installation or operational factors can increase radial thrust, potentially affecting pump components and service life.

In essence, understanding and managing radial thrust in pumps involves a delicate interplay between design, operating conditions, and inherent system dynamics. Mitigating excessive radial thrust requires a comprehensive approach that considers design specifics, operational nuances, and manufacturer recommendations.

The effects of high radial thrust can also lead to other issues, such as increased shaft deflection, premature wear and failure of radial bearings, higher shaft stress, potential mechanical seal problems, increased radial vibration, and potential pump failure during continuous operation.

Typical mitigation strategies for high radial thrust include modifying the outlet (discharge) pump casing type (i.e., switching from a single volute to a double volute), trimming the impeller to match design conditions, limiting the AOR to a percentage of the BEP that ensures adequate bearing life and minimal shaft deflection, designing pumps with limited impeller width, and changing the pump type.

A comprehensive understanding of radial thrust lays the foundation for efficient and long-term pump operation, emphasizing the importance of design considerations and optimal operational practices. Balancing these aspects ensures the pump’s service life and peak performance across various applications, thereby securing its critical role in diverse industries.