Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Cooling Water Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Hand Pump

-

Marine Pump Parts

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-13452620990

WhatsAPP/WeChat :+86-13452620990

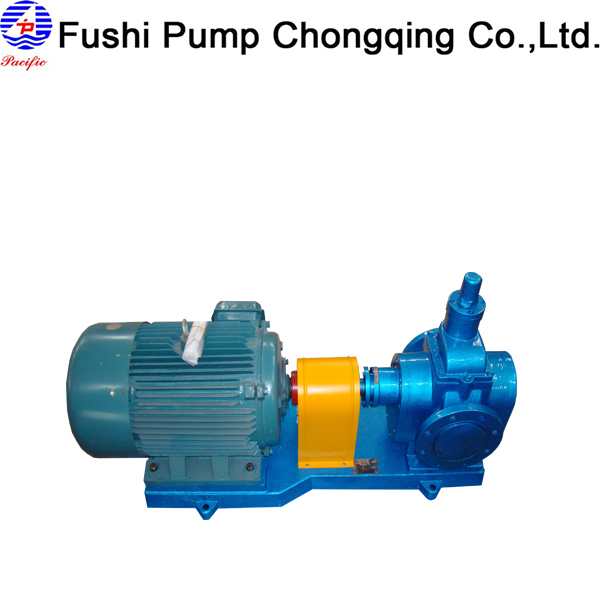

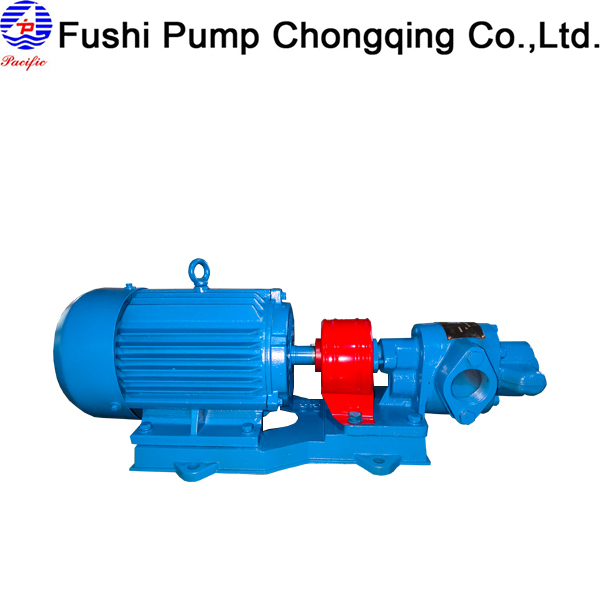

Marine Gear Pump

Date:2026-01-04Views:

Marine Gear Pump

I. Product Overview

Marine gear pump is a core power transmission equipment in marine power systems and fluid conveying systems. Relying on the rotational movement of a pair of high-precision meshing gears to generate volume changes, it achieves negative pressure suction and pressurized discharge. It has core advantages such as compact structure, high volumetric efficiency and strong impact resistance, and can stably convey various high-viscosity fluid media such as fuel oil, lubricating oil and hydraulic oil. The product adopts stainless steel, cast iron, copper and other main materials, and the gears are made of high-quality alloy steel such as 20CrMnTi through precision heat treatment. It is suitable for fluid media with viscosity of 20-1500cSt, operating temperature range of -25℃~150℃, and service life of ≥10 years. It fully complies with IMO "Code for the Safety of Machinery Systems of Ships" (MSC.389(94)) and ISO 3055 marine gear pump performance standards, has obtained type approval from mainstream classification societies such as RS, LR, ABS and CCS, and is widely used in key scenarios such as fuel supply for main engines of cargo ships, hydraulic systems of oil tankers, power lubrication of fishing boats and oil supply for auxiliary equipment of passenger ships.

II. Core Technologies

1. Key Technical Parameters

Flow Range: 5-100m³/h, suitable for equipment power of 500-20000kW (e.g., 10000kW main engine requires flow ≥50m³/h)

Output Pressure: 0.5-3.0MPa, which can meet the pressure requirements of high-pressure common rail fuel systems (1.5-3.0MPa), conventional lubrication systems (0.5-1.0MPa) and other different systems

Medium Compatibility: Can convey No. 0 diesel, heavy fuel oil (HFO), 150# gear oil, 46# anti-wear hydraulic oil, etc. Suitable for fluid media with viscosity of 20-1500cSt and operating temperature of -25℃~150℃ (heavy oil needs to be preheated to above 60℃)

Speed Range: 500-3000r/min, accurately matched with the speed of marine diesel engines and generators, no additional transmission device is required

Volumetric Efficiency: ≥95% (under rated working conditions), 5%-8% higher than ordinary gear pumps, with lower energy consumption

Self-priming Performance: Self-priming height ≥2.5m, priming time ≤60 seconds (for No. 0 diesel), which can directly suck liquid from low-lying cabins without manual priming

2.Safety protection design

Explosion-proof Certification: The motor can be optional with Ex d IIB T4 Gb explosion-proof grade, suitable for Zone 1 hazardous areas near fuel tanks, effectively preventing the risk of oil-gas explosion

Overload Protection: Built-in relief valve, which automatically opens to relieve pressure and return oil when the outlet pressure exceeds 1.2 times the rated value, avoiding overload damage to the pump body and pipeline

Anti-leakage Structure: Adopts double mechanical seal + skeleton oil seal combined design, with leakage ≤0.01mL/h, complying with marine sealing safety standards

Anti-vibration Design: The pump body and base are connected by rubber shock-absorbing pads, which can withstand the impact of ship heel ±20°, trim ±15° and vibration acceleration 12g, with flow attenuation ≤3%

III. Technical Advantages and Innovative Design

1. Efficient and Stable Conveying Core

Precision Gear Meshing Technology: The gears adopt hard surface nitriding treatment (surface hardness HRC≥60), and the tooth profile is precision ground. The meshing gap is ≤0.02mm, ensuring stable operation without pulsation and pressure fluctuation ≤±0.05MPa

Optimized Flow Channel Design: The oil inlet and outlet adopt gradually expanding flow channels, which reduce fluid resistance and improve the conveying efficiency of high-viscosity media. The conveying capacity for 1000cSt heavy oil is 15% higher than that of ordinary gear pumps

High-temperature Adaptation Upgrade: The pump body adopts an integrated design of cast iron + cooling fins, which can operate continuously without overheating under 150℃ high-temperature working conditions, suitable for tropical sea areas and high-temperature fuel conveying scenarios

2. Wear Resistance and Impact Resistance Enhancement

Gear Material Upgrade: Selected alloy steel, through carburizing, quenching, tempering and other heat treatment processes, the wear resistance is improved by 30%, and the service life is ≥10000 hours

Optimized Bearing Configuration: Adopts imported high-temperature resistant deep groove ball bearings, with strong bearing capacity, stable operation under high-temperature and high-vibration working conditions, and the failure rate is reduced by 40%

Shell Reinforcement Design: The wall thickness of the pump body is uniformly thickened, and key parts adopt reinforcing rib structure. The compressive strength is improved by 20%, which can withstand extreme impacts such as ship collision

3. Wide Working Condition Adaptability

Multi-medium Compatibility: By replacing seals and gear bushings of different materials, it can adapt to various media such as fuel oil, lubricating oil and hydraulic oil, realizing "one pump for multiple uses" and reducing the purchase cost of marine equipment

Low-temperature Startup Guarantee: The pump body can be optionally equipped with an electric heating jacket (power 300-500W), which can quickly preheat under -25℃ low-temperature environment to ensure smooth startup, suitable for polar and frigid sea area ships

Intelligent Linkage Control: Optional flow, pressure and temperature sensors can be linked with the ship's central control system in real time to realize abnormal alarm, automatic shutdown, remote monitoring and other functions, making operation and maintenance more efficient

4. Maintenance Convenience Improvement

Modular Structure Design: The pump cover, gears, bearings and other components adopt quick-release connection. Daily maintenance does not require disassembly of the entire pipeline, and the replacement time of wearing parts is ≤30 minutes

Generalization of Wearing Parts: The generalization rate of gears, seals and other wearing parts of different flow models is ≥85%, which reduces the pressure of marine spare parts inventory and lowers the operation and maintenance cost

Self-cleaning Function: The flow channel adopts large-curvature arc transition (R≥15mm) to reduce medium residue. Basic cleaning can be completed by passing clean water before shutdown, and the maintenance cycle is extended to 2000 hours

IV. Typical Application Scenarios

1. Fuel Conveying System

Cargo Ship Main Engine Fuel Supply: The 10000kW cargo ship main engine adopts 316L stainless steel marine gear pump (flow 50-60m³/h, pressure 2.5MPa) to convey low-sulfur diesel (sulfur content ≤0.5%) to the high-pressure oil pump. The precision meshing design ensures stable oil supply and improves the main engine combustion efficiency by 3%-5%

Oil Tanker Heavy Oil Conveying: Ocean-going oil tankers adopt high-temperature gear pumps (flow 80-100m³/h, pressure 1.8MPa) to convey heavy diesel oil (HFO) preheated to 80℃. The high-temperature resistant sealing design ensures continuous operation without leakage, suitable for the long-term navigation needs of oil tankers

2. Lubrication System

Marine Diesel Engine Lubrication: The 5000kW diesel engine is equipped with a high-strength cast iron gear pump (flow 30-40m³/h, pressure 1.0MPa) to convey 46# anti-wear hydraulic oil to key components such as crankshaft and camshaft, ensuring uniform lubrication and reducing component wear

Reduction Gearbox Lubrication: The large cargo ship reduction gearbox adopts alloy cast iron gear pump (flow 20-25m³/h, pressure 1.2MPa) to convey 150# gear oil. The impact-resistant design is suitable for the high-frequency vibration working condition of the gearbox, ensuring the stable operation of the lubrication system

3. Hydraulic and Emergency Systems

Deck Machinery Hydraulic Oil Supply: Coastal passenger ship deck cranes and windlasses adopt small gear pumps (flow 5-10m³/h, pressure 2.0MPa) to convey 68# hydraulic oil. The compact structure is suitable for installation in narrow spaces on the deck with quick response

Emergency Fuel Supply: Fishing boats and small cargo ships are equipped with portable gear pumps (flow 3-5m³/h, pressure 0.8MPa), which are made of aluminum alloy with weight ≤25kg. They are driven by hand-cranking + electric dual modes and can quickly start emergency fuel supply when the main system fails

4. Special Fluid Conveying

Research Vessel Reagent Conveying: Ocean-going research vessels adopt 316L stainless steel gear pumps (flow 2-5m³/h, pressure 0.6MPa) to convey low-concentration chemical reagents. The corrosion-resistant material ensures no pollution to the purity of reagents, and the precise flow control guarantees the accuracy of experimental data

Polar Ship Fuel Conveying: Polar research vessels adopt gear pumps with heating jackets (flow 15-20m³/h, pressure 1.5MPa), which can preheat fuel to 20℃ in -25℃ environment, ensuring smooth conveying without icing and blockage risks

Product showcase:(In addition, please provide the parameter of the marine pump you need and we can customize the suitable type for you.)

| Marine Gear Pump | ||

|

| |