Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Cooling Water Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Hand Pump

-

Marine Pump Parts

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-13452620990

WhatsAPP/WeChat :+86-13452620990

Marine Piston Pump

Date:2026-01-07Views:

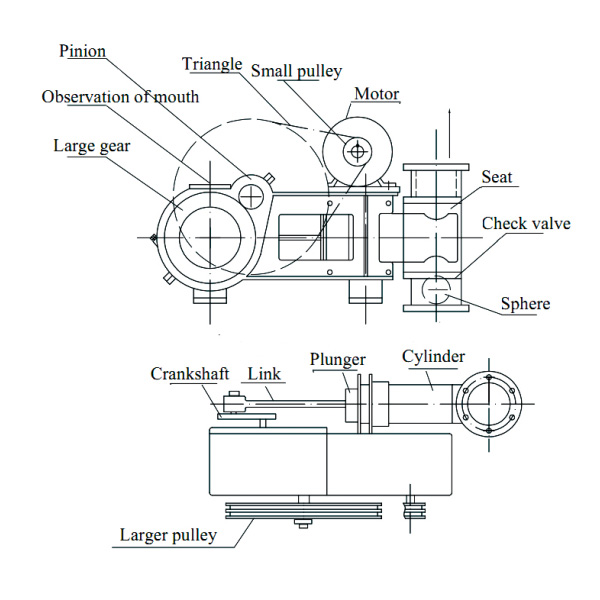

Marine Piston Pump

I. Product Overview

Marine Piston pump is the core power source equipment of the ship's hydraulic system, specially designed to provide stable high-pressure oil source for various high-pressure hydraulic actuators of the ship (cargo winch, windlass, steering gear, bow thruster, deck machinery, etc.). Its core function is to realize the suction and discharge of oil through the reciprocating motion of the plunger, efficiently convert mechanical energy into hydraulic energy, and ensure the precise and heavy-load operation of the ship's key machinery. Equipped with high-precision sealing components and reinforced drive mechanism, it has the characteristics of high-pressure output, high volumetric efficiency, stable operation and strong resistance to impact load, and can adapt to complex marine environments such as high humidity, strong salt spray, severe vibration and variable working conditions faced by various ocean-going and coastal ships.

As the "power heart" of the ship's hydraulic system, marine plunger pump strictly complies with international and domestic standards such as the International Convention for the Safety of Life at Sea (SOLAS), IMO Marine Machinery Equipment Rules, GB/T 10832-2011 *Marine Pumps* and GB/T 23537-2009 *Hydraulic Plunger Pumps*. It has obtained certifications from mainstream classification societies such as China Classification Society (CCS), American Bureau of Shipping (ABS) and Lloyd's Register (LR), and is widely used in various ships including 500-200000 ton ocean-going cargo ships, oil tankers, container ships, LNG ships, ro-ro passenger ships, offshore operation platforms and special engineering ships (salvage ships, crane ships). Compared with gear pumps and vane pumps, marine plunger pump has higher working pressure and volumetric efficiency, which can meet the high-pressure power demand of ship's heavy-load machinery. At the same time, through modular design and intelligent control upgrading, it adapts to the development trend of modern ship automation and intelligence, and is the preferred power equipment for ship's key hydraulic systems.

II. Core Technical Parameters

Pressure Range: Rated working pressure 0.19-0.29 Mpa, which can be customized in grades according to the needs of the hydraulic system. The pressure fluctuation error is ≤±1%, ensuring stable high-pressure power output and adapting to heavy-load machinery working conditions.

Flow Range: 0.1-10 m³/h, supporting variable adjustment (displacement adjustment range 10%-100%). It can realize precise flow matching through electro-hydraulic proportional control, and the flow stability error under rated working conditions is ≤±2%, meeting the power demand under different loads.

Drive Mode: Mainly adopts special marine asynchronous motor drive (protection class IP55, insulation class F), with optional hydraulic motor drive or diesel engine drive mode; the motor supports 220V/380V/440V marine standard voltage, and the drive system has overload, overheating, phase loss and pressure abnormality protection functions, which can be linked with the ship's central control system (PLC) to realize automatic start-stop and variable adjustment.

Operating Performance: Volumetric efficiency ≥95%, total efficiency ≥90%; Net Positive Suction Head (NPSH) ≤2.5 m, strong self-priming capacity (self-priming height ≥1.5 m, self-priming time ≤30 seconds); operating noise ≤72 dB(A), vibration acceleration ≤0.8 m/s²; continuous operation life ≥12000 hours, supporting 24-hour continuous heavy-load operation, adapting to the uninterrupted operation needs of the ship.

III. Structural Design and Core Advantages

3.1 Core Structural Design

High-Precision Plunger-Cylinder Coupling Structure: The plunger and cylinder block are processed by precision honing, and the fit clearance is controlled at 0.002-0.005 mm to improve sealing performance and volumetric efficiency; the cylinder block adopts a rotary design, matched with a wear-resistant port plate to realize shockless oil distribution, reduce the damage of high-pressure oil impact to components, and extend service life.

Reinforced High-Pressure Sealing System: Adopts a dual structure of "composite seal + pressure compensation seal", optimizes the seal lip structure according to the reciprocating motion trajectory of the plunger, which can effectively resist high-pressure oil leakage (leakage ≤0.1 mL/min); equipped with a seal chamber pressure monitoring device to feedback the seal state in real time and avoid hydraulic system failures caused by seal failure.

Anti-Vibration and Wear-Resistant Protection Design: The pump body adopts an integral casting + reinforcing rib reinforcement structure to improve impact resistance rigidity; the drive shaft adopts spline connection, matched with an elastic coupling to buffer vibration, avoiding transmission deviation caused by ship turbulence; key moving parts (plunger, bearing) adopt dual lubrication of grease + circulating oil to improve wear resistance and adapt to severe vibration working conditions.

3.2 Core Technical Advantages

Stable and Reliable Operation: The precise plunger-cylinder coupling design and wear-resistant port plate structure ensure stable operation under high-pressure working conditions, small fluctuations in pressure and flow, and avoid hydraulic system impact; high-strength alloy material and reinforced sealing design can resist the erosion of marine high-salt spray and high-temperature environment, with low failure rate, ensuring the continuous operation of ship's key machinery.

Convenient Maintenance and Long Service Life: Key components adopt modular design, and wearing parts such as plungers, seals and bearings can be quickly disassembled and replaced with special tools without overall disassembly of the pump body; daily maintenance only needs to regularly check oil cleanliness, supplement grease and monitor seal state, with a long maintenance cycle (regular maintenance interval ≥6 months), reducing the maintenance workload and operation cost of crew.

Safe, Compliant and Intelligent Linkage: Strictly follows international and domestic ship safety and hydraulic system standards, and has passed multiple rigorous tests by classification societies such as high-pressure performance test, vibration test, salt spray corrosion test and high-low temperature operation test; supports linkage with ship's PLC system and monitoring system to realize remote monitoring and intelligent diagnosis, adapting to the needs of modern ship automatic operation and maintenance.

IV. Typical Application Scenarios

4.1 Marine Cargo Winch Hydraulic System

Cargo winch is the core equipment for ship cargo loading and unloading, which requires high-pressure power to ensure heavy-load lifting and precise positioning. The marine plunger pump can provide 25-40 MPa stable high-pressure oil source to drive the cargo winch hydraulic motor for efficient operation; the variable adjustment function can automatically match the flow according to the cargo weight, realizing fast lifting to improve efficiency under light load and stable operation to ensure safety under heavy load; the anti-vibration structure adapts to the turbulent working conditions during ship navigation, ensuring continuous and stable loading and unloading operations.

4.2 Fuel Supply for Passenger Ships/Luxury Yachts

Windlass and mooring equipment need to realize rapid anchoring and precise mooring under severe sea conditions, which have extremely high requirements on the reliability of hydraulic power. Marine plunger pump has strong impact load resistance, which can cope with the instantaneous high-pressure impact during anchoring; high-pressure output ensures that the windlass can easily anchor in deep water (≤100 meters); the intelligent control function can be linked with mooring sensors to realize automatic adjustment of anchor chain tension and avoid equipment damage due to overload.

4.3 Marine Steering Gear Hydraulic System

The steering gear is the key equipment for ship course control, which requires hydraulic power to achieve precise and rapid steering. The marine plunger pump adopts a dual-pump redundancy design (main pump + standby pump) to ensure uninterrupted power supply for the steering gear; the precise flow adjustment function can realize stable steering and positioning of the rudder blade with a steering error ≤ 0.5°; it has excellent high-pressure sealing performance, avoiding steering gear failure caused by hydraulic oil leakage and ensuring stable ship navigation course.

4.4 Marine Deck Machinery (Crane, Winch) Hydraulic System

Deck machinery such as cranes and winches have complex operating conditions and need to frequently switch loads and speeds. The variable adjustment function of the marine plunger pump can quickly respond to load changes, realizing stable start-stop and speed regulation of the machinery; the high-pressure output can drive cranes to lift heavy cargo over long distances; the anti-salt spray and anti-vibration design is suitable for the harsh outdoor environment of the deck, extending the service life of the equipment.

4.5 Special Ship Hydraulic System (Salvage Ship, Crane Ship)

The hydraulic systems of special ships such as salvage ships and crane ships need to withstand extreme heavy loads and complex operating conditions, which have strict requirements on the high-pressure performance and reliability of the pump. The marine plunger pump adopts a high-strength cast steel pump body and wear-resistant alloy plungers, with a rated working pressure of up to 40-45 MPa, which can drive lifting equipment to hoist and salvage thousands of tons of heavy objects; the intelligent monitoring system can real-time monitor the operating status of the pump body, early warn of faults, and ensure the safe and efficient development of special operations.

Performance Parameter