Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Cooling Water Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Hand Pump

-

Marine Pump Parts

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-13452620990

WhatsAPP/WeChat :+86-13452620990

Marine Cooling Water Pump

Date:2026-01-04Views:

Marine Cooling Water Pump

Overview

The marine cooling water pump is a critical component of a vessel’s power system, providing circulating cooling water for engines, generators, and auxiliary equipment to ensure optimal operating temperatures. Compliant with energy efficiency and environmental standards, it is suitable for bulk carriers, container ships, LNG carriers, and more, balancing reliability and energy savings.

Marine Cooling Water Pump

I. Product Overview

Marine cooling water pumps are core temperature control and protection equipment for ship power systems and auxiliary equipment. Based on centrifugal or positive displacement conveying principles, they circulate cooling media such as seawater and fresh water to components requiring temperature reduction, including main engines, auxiliary engines, generators, and air conditioning systems. This enables rapid heat transfer and dissipation, ensuring equipment operates stably within the rated temperature range. The product features core advantages such as stable flow rate, high heat exchange efficiency, salt spray corrosion resistance, and vibration/impact resistance. It is compatible with both fresh water cooling systems and seawater cooling systems, and can handle various cooling media including clean fresh water, seawater with solid content ≤1% (particle size ≤2mm), and 20%-50% ethylene glycol antifreeze. The main body is made of corrosion-resistant and wear-resistant materials such as 316L stainless steel, cast iron, and copper, with impellers integrally formed from engineering plastics or aluminum alloy. It is suitable for media temperatures ranging from -20℃ to 130℃ and has a service life of ≥12 years. Fully complying with IMO "Code for the Safety of Ship Machinery Cooling Systems" (MSC.427(98)) and ISO 9906 marine pump performance standards, the product has obtained type approval from mainstream classification societies such as CCS, LR, ABS, and RS. It is widely used in power temperature control and air conditioning cooling systems of various ships, including cargo ships, oil tankers, passenger ships, fishing boats, research vessels, and polar ships.

II. Core Technologies

1. Key Technical Parameter

Flow Range: 10-500m³/h, suitable for ship power of 500-50000kW (e.g., 30000kW main engine requires flow rate ≥300m³/h)

Output Pressure: 0.5-3.0MPa, which can meet different pressure requirements such as main engine cylinder liner cooling (1.5-2.5MPa), auxiliary engine cooling (0.8-1.2MPa), and air conditioning cooling (0.5-0.8MPa)

Medium Compatibility: Capable of conveying clean fresh water, seawater with solid content ≤1% (particle size ≤2mm), and 20%-50% ethylene glycol antifreeze; suitable for media temperatures ranging from -20℃ to 130℃

Speed Range: 1000-3600r/min, accurately matched with the speed of marine diesel engines and generators, enabling direct linked drive without additional transmission devices

Heat Exchange Efficiency: The heat exchange efficiency of the supporting cooling system is ≥95%, which can stably control the main engine cylinder liner temperature within the rated range of 85-95℃

Self-priming Performance: Self-priming height ≥2.0m, priming time ≤80 seconds (for clean water); can directly extract liquid from the ship's low-lying cooling cabin without manual priming

Net Positive Suction Head (NPSH): ≤3.0m, effectively avoiding impeller damage caused by cavitation in seawater cooling scenarios and improving operational stability

2. Safety Protection Design

Anti-cavitation Protection: The impeller adopts an anti-cavitation blade design, with an inducer added at the inlet. Combined with low NPSH parameters, it can avoid cavitation under harsh conditions of seawater temperature 35℃ and salinity 3.5%

Overload Protection: Built-in mechanical seal temperature monitoring and motor overload protection devices. When the seal temperature ≥120℃ or the motor current exceeds 1.1 times the rated value, an alarm is automatically triggered and the machine shuts down

Vibration and Impact Resistance: The pump body and base adopt a dual shock absorption structure of rubber shock pads + springs, which can withstand ship heel ±25°, trim ±15°, and vibration acceleration of 12g, with flow attenuation ≤3

III. Technical Advantages and Innovative Design

1. High-Efficiency Cooling Core Upgrade

2. Enhanced Corrosion and Wear Resistance

3. Easy Operation and Maintenance

Standby Switching Function: The dual-pump parallel system supports automatic switching. When the main pump fails, the standby pump can start within 3 seconds to ensure continuous operation of the cooling system without interruption

Anti-corrosion and Explosion-proof Design: Seawater cooling models adopt all stainless steel materials + cathodic protection devices, improving corrosion resistance in salt spray environments by 50%; models installed near fuel tanks can be equipped with Ex d IIB T4 Gb explosion-proof motors, suitable for Zone 1 hazardous areas

4. Wide Scene Adaptability

Optimized Impeller Design: Adopts a twisted blade impeller optimized by 3D fluid simulation, improving hydraulic efficiency by 8%-12%. Under the same power, the flow rate is 15% higher than that of traditional impellers, with better heat exchange efficiency

IV. Typical Application Scenarios

Intelligent Temperature Control Linkage: Optional temperature sensors and frequency conversion control systems can automatically adjust the pump speed according to the main engine load, achieving precise flow matching, reducing energy consumption by 15%-20%, and avoiding energy waste caused by overcooling

Double-Circulation Adaptive Structure: Supports "fresh water-seawater" dual-circuit switching. Through a built-in reversing valve, the cooling medium can be flexibly switched in different sea area temperature environments, ensuring no freezing in low-temperature sea areas and sufficient cooling in high-temperature sea areas

1. Main Engine Cooling System

Impeller Wear Resistance Upgrade: Seawater cooling model impellers are made of duplex stainless steel (2205) with a plasma-sprayed ceramic coating on the surface, hardness ≥HRC65, improving wear resistance by 60%, and can withstand long-term scouring of sediment in seawater

2. Auxiliary Engine and Generator Cooling

Seal Upgrade Design: Adopts a cartridge mechanical seal with a built-in elastic compensation mechanism, which can automatically compensate for wear gaps, leakage ≤0.01mL/h, and seal life increased to more than 8000 hours

Full-Process Anti-Corrosion Treatment: The pump shaft is made of stainless steel + nitriding treatment, and the mechanical seal uses silicon carbide-graphite paired materials with strong corrosion resistance; the external surface of the pump body undergoes double anti-rust treatment of galvanizing + passivation, with corrosion resistance time ≥1500 hours in salt spray environments

3. Air Conditioning and Living System Cooling

Modular Structure Design: Core components such as the pump cover, impeller, and seals adopt quick-release connections. Daily maintenance does not require disassembly of the entire pipeline, and the replacement time of wearing parts is ≤30 minutes

Generalization of Wearing Parts: The generalization rate of wearing parts such as impellers, seals, and bearings for different flow models is ≥85%, reducing the inventory pressure of ship emergency spare parts and lowering operation and maintenance costs

Visual Status Monitoring: The pump body is equipped with pressure gauges, thermometers, and vibration sensors to display key operating parameters in real time; an optional remote monitoring module can synchronize data to the ship's central control system, allowing operation and maintenance personnel to grasp the equipment status remotely

4. Special Ship and Equipment Cooling

Extreme Temperature Adaptation: Low-temperature models can be equipped with electric heating jackets (power 500W), which can quickly preheat the pump body and medium in -20℃ environments to avoid freezing and blockage; high-temperature models use high-temperature resistant bearings and seals, which can adapt to 130℃ high-temperature cooling media

Miniaturized and Portable Design: Portable cooling water pumps (weight ≤30kg) are optional for cooling auxiliary equipment of small and medium-sized ships. Equipped with handles and quick connectors, they can be flexibly moved to adapt to the cooling needs of different equipment

Special Ship Adaptation: Polar ship models adopt low-temperature resistant stainless steel materials + thermal insulation layer design, which can operate stably in -30℃ polar environments; deep-sea research vessel models adopt high-pressure sealing structures, which can adapt to the high-pressure cooling needs of deep-sea detection equipment

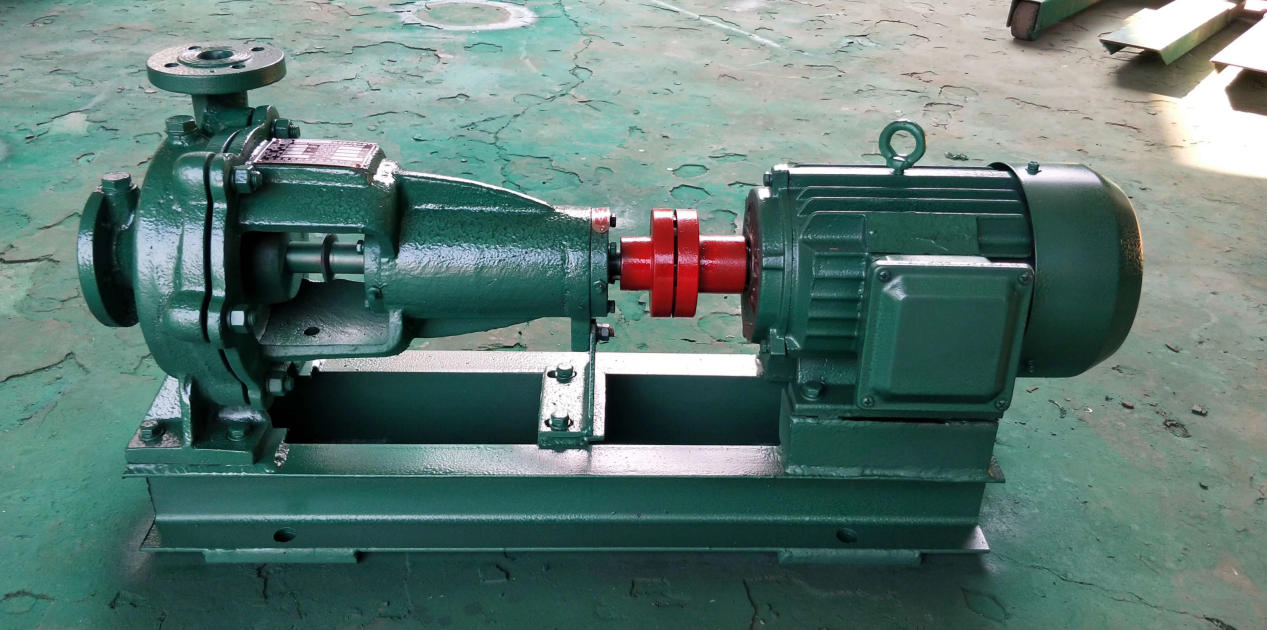

Product showcase:(In addition, please provide the parameter of the marine pump you need and we can customize the suitable type for you.)

| Marine Cooling Water Pump | ||||

|

|

|

| |

The picture of pump