Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Cooling Water Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Hand Pump

-

Marine Pump Parts

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-13452620990

WhatsAPP/WeChat :+86-13452620990

Working Principle of Mechanical Seals

Date:2026-01-06Views:

Working Principle of Mechanical Seals

I. Overview of Mechanical Seals

Mechanical seals, also known as face seals, are critical devices designed to solve sealing issues between rotating shafts and machine bodies. They rely on the combined action of fluid pressure, elastic force from the compensation mechanism (or magnetic force), and auxiliary seals to maintain close fitting and relative sliding, effectively preventing fluid leakage. Widely used in rotating fluid machinery such as pumps, compressors, and reaction mixers, as well as in sealing applications like gearboxes and marine tail shafts, mechanical seals demonstrate broad applicability as universal shaft sealing devices.

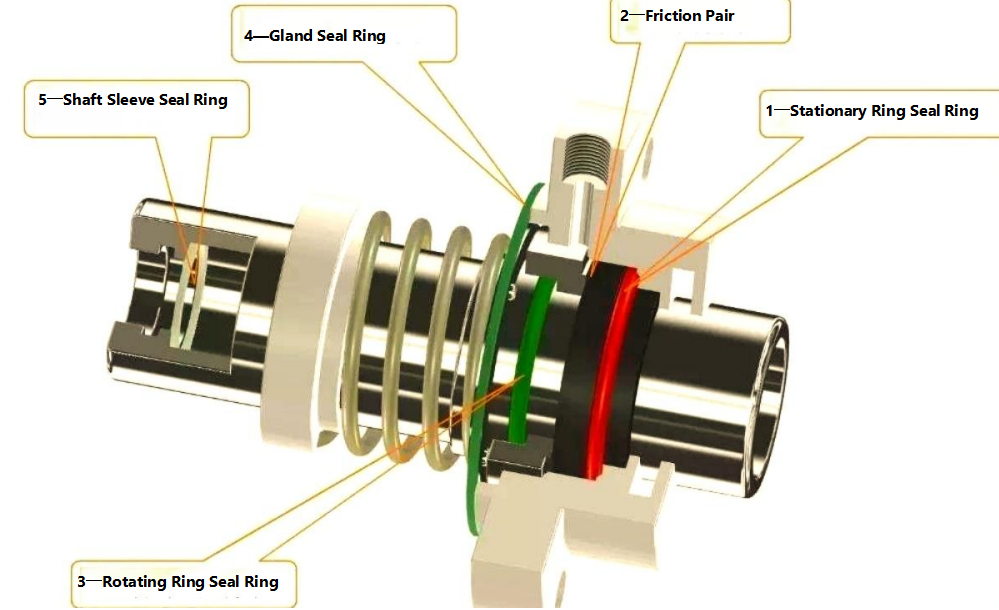

The structural design of mechanical seals is highly flexible, with face seals being the most common form. They consist of a static ring and a dynamic ring, forming a friction pair responsible for preventing medium leakage. Both rings must exhibit excellent wear resistance, while the dynamic ring should move axially to automatically compensate for sealing surface wear and ensure tight fitting with the static ring. The floating design of the static ring also provides buffering to optimize sealing performance.

Basic components of a mechanical seal include the static ring, dynamic ring, gland, thrust ring, spring, locating ring, shaft sleeve, dynamic ring seal, static ring seal, and shaft sleeve seal. Elastic elements like springs and bellows primarily undertake pre-tightening, compensation, and buffering tasks, requiring corrosion and fatigue resistance to ensure sufficient elasticity to overcome friction and inertia, maintaining good fitting of the face seal pair.

Auxiliary sealing elements (e.g., O-rings, V-rings, U-rings, wedge rings, and special-shaped rings) are mainly responsible for sealing the static and dynamic rings, while also providing floating and buffering functions. They must ensure sealing between the static ring and gland, between the dynamic ring and shaft/shaft sleeve, and the floating ability of the dynamic ring. In material selection, these auxiliary seals also require heat resistance and other properties to ensure long-term stability.

1. Basic Structure

(1) Buffer Compensation and Pressing Mechanism

(2) Transmission Mechanism

2. Key Sealing Points

(1) Auxiliary Seal between Static Ring and End Cover

(2) Seal at the Connection between End Cover and Pump Body

II. Working Principle of Mechanical Seals

The working principle of a mechanical seal relies on one or more pairs of end faces that slide relative to the shaft perpendicularly. Under the combined action of fluid pressure and the elastic force (or magnetic force) of the compensation mechanism, these faces maintain close fitting and relative sliding through the cooperation of auxiliary seals. This design effectively prevents fluid leakage.

III. Diversity and Application of Sealing Materials

The selection of sealing materials must meet specific sealing functions, as different sealing media and equipment working environments pose unique adaptability challenges. Generally, sealing materials should possess the following characteristics:

Good material compactness to effectively prevent medium leakage.

Excellent compressibility and resilience, ensuring permanent deformation is minimized.

Outstanding corrosion resistance, enabling long-term stable operation in complex media such as acids, alkalis, and oils, with minimal changes in volume and hardness, and no adhesion to metal surfaces.

Softness when combined with the sealing surface to ensure sealing effectiveness.

Easy manufacturing, cost-effective, and readily available raw materials.

IV. Key Technologies for Installation and Use of Mechanical Seals

Mastering a series of key technologies is essential during the installation and use of mechanical seals to ensure optimal sealing performance. These technologies include, but are not limited to, the correct selection and matching of sealing materials, rational adjustment and optimization of mechanical seal structural parameters, and the mastery of proper installation and usage methods. Through the comprehensive application of these technologies, the reliability and service life of mechanical seals can be effectively improved.

The radial runout of the equipment shaft should be controlled within 0.04 mm, and the axial axial play should not exceed 0.1 mm.

Collision and hammering are strictly prohibited during installation to prevent damage to the mechanical seal friction pair and resulting sealing failure.

When installing the static ring gland, screws should be tightened evenly to ensure the static ring end face is perpendicular to the axis line.

After installation, rotate the shaft by hand, which should feel smooth without obstruction.

Additionally, mechanical seals adopt a shallow groove design with film thickness and groove depth reaching the micrometer level, equipped with lubrication grooves, radial sealing dams, and circumferential sealing weirs, collectively forming the sealing and bearing parts. This shallow groove sealing technology combines the advantages of planar sealing and grooved bearings, featuring small leakage, large film thickness, non-contact friction, low power consumption, and low heat generation.